Background

Vinyl Thai Public Company Limited is a fully integrated producer of PVC polymers in its plant in Map Ta Put on the Eastern Seaboard region of Thailand. As well as producing PVC, the plants site includes a Vinyl Monomer Plant (VCM), Ethylene Dichloride Plant (EDC) and a Chlor Alkali Plant (MCA). As part of the plants expansion in 2005/2006 a large Hot Quench column was built to handle and process high temperature and high-pressure alkali and acidic gases.

Operating Conditions

Gaseous phases produced during the plants operation have to be rapidly cooled to control the temperature for further up stream operations. To do this a specially engineered hot quench column is required that works to the following conditions

- Max. Design Temperature 232ºC

- Max. Operating Temperature 95ºC

- Max. Design Pressure 6 bar

- Max. Operating Pressure 3 bar

- Regents: HCl, NaOH, Water and Organics

Special Requirements

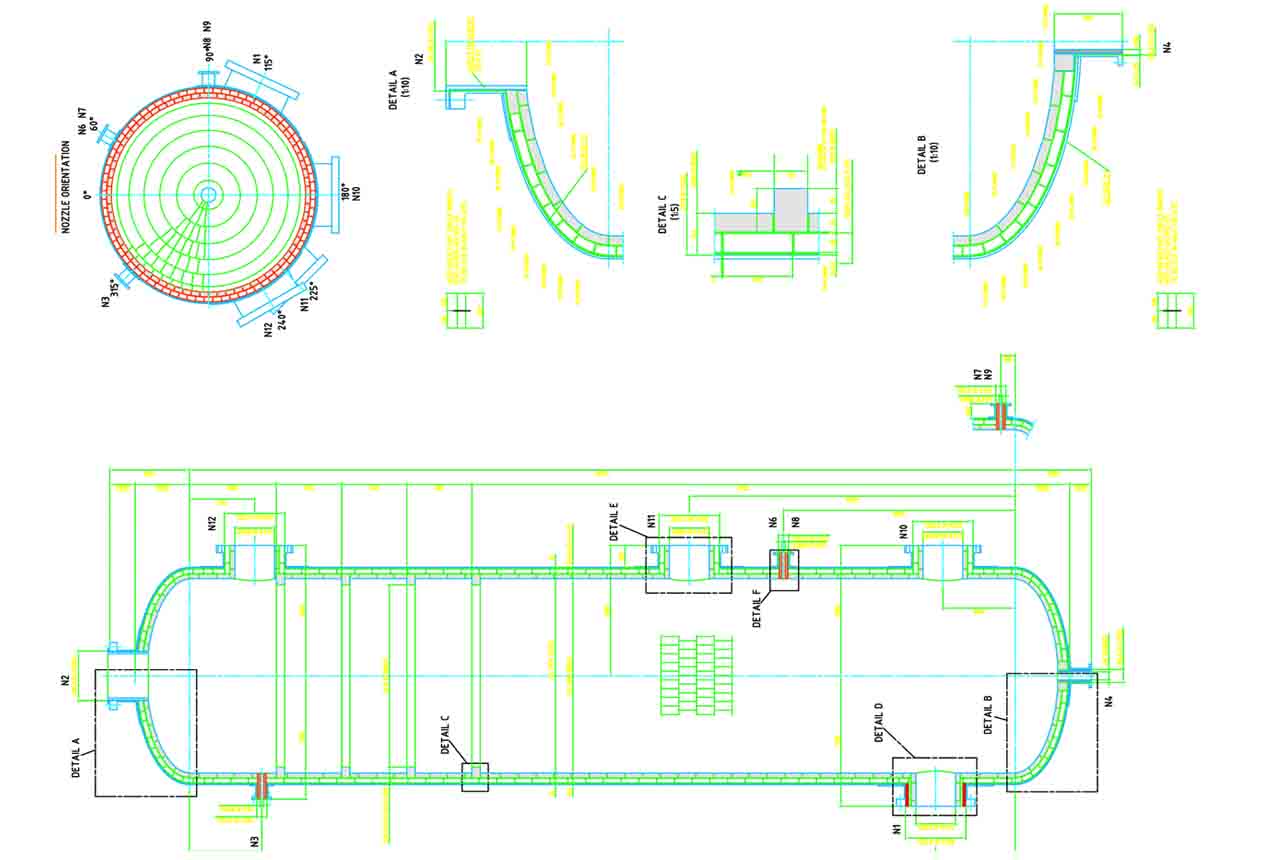

The Shell of the Hot Quench was produced in mild steel, with specially produced titanium internal trays and nozzle linings. The harsh environment of high temperature, high pressure and highly acidic and alkali conditions resulted in a special protective lining being required. consisting of many layers to withstand the extreme conditions

Corrosion Protection

This type of vessel requires a complicated lining to protect the steel shell surfaces, as well as layer of bricks to protect the steel shell corrosion barrier from the high temperatures and pressures. Nozzles were also protected with complex sleeves made of carbon graphite and sealed with foamglass and PTFE seals.

System

The corrosion protection system comprised of many layers to be able to operate in the extreme conditions This consisted of a synthetic rubber sheet lining, following by a Furane FRP lining, a 65mm ceramic brick lining bedded in Furane cement, a 65 Carbon Brick Lining bedded in Carbon Filled Furane Cement and fnally Sealed with a Novalac resin. Special Furane resins were used on flange faces and nozzles were protected with brick linings, carbon graphite or titanium sleeves.

Project Details

| Location | Rayong, Thailand |

| Project | Chlor Alkali Plant Expansion |

| Owner | Vinythai Public Company Limited |

| EPC | Toyo-Thai Corporation Public Company Limited |

| Date | 2006 |

| Work | Hot Quencher Absorber Column |

| System | Multi Layer Brick Lining |

| Area | 135 m2 |

| Value | US$ 400,000 |

Thai

Thai